Rastgele ürün Rastgele ürün |

|

Prefabrik Konteyner 240*270*750cm 2000Kg ( 4.999€ )+kdv ADRESE TESLİM

Yorumlar: 0

KASATASCELİKPARAKASALARI05322152522

Malın Satış Fiyatı ve Birim Fiyatının Uygulanmaya Başladıgı Tarih: 01.01.2026

|

|

| Kasatas Online |

25 Yıllık Tecrübesiyle

Uzman Pazarlama Direktörü

GSM: 90(532) 215 25 22

Haluk DÜNDAR

Get Help

+90342 235 00 90

Haluk DÜNDAR

KASATAŞ Elektronik 2.000 m² kapalı alana sahip montaj tesisi ile, CE, TUV, ISO 9002 gibi dünya standartlarına haiz ithal kilitleme mekanizmalarının çelik para kasaları ve kapılar üzerine montajını gerçekleştirmektedir. Kısa süre içerisinde imalat sektöründe de kalite anlayışını ispat etmiş, ithalatın yanında, ülkemizin Dünya 'ya ihracat potansiyeli içinde yerini almıştır.

2014 yılinda Türkiyedeki çelik kasa firmalarindan sadece Firmamız Kasataş a.ş. tarafindan Türkiye genelindeki tüm polis asayiş şube müdürlüğü hırsızlık büro amirliği ne bağlı 100 polise çelik kasa hırsızlıgı ile ilgili daha dogru tespit ve analiz yapabilmeleri için bilgilendirme egitimi semineri verilmiştir.

Ayrıca güvenilir bir çelik para kasalarında bulunması gereken özellikler kg kilit zırh özellikleri ile genel bilgiler verilmiştir. İhtiyacın kapsamını belirleyin.

a. Çelik Kasa seçiminde ilk adım ihtiyacınızı belirlemektir. Böylece satış danışmanınız size doğru fiyat aralıgında tip ve ebatlarda çelik kasa önerebilecek, kararınızı doğru vermenizi sağlayacaktır.

b. Neleri kasada muhafaza edeceğinizi düşünün; Muhasebe defterleri, sözleşmeler, tapu ve senetler, kimlik belgeleri, ruhsat ve pasaportlar, kitap, mücevherat, silah, laptop, tablet, saat, kamera, para, çeşitli koleksiyonlar vb.

c. Kasayı yerleştireceğiniz yeri belirleyin ve İhtiyacınızınız da göz önünde bulundurarak çelik kasanın ölçülerini belirleyin. Çelik Kasayı koymayı düşündüğünüz yere bağlı olarak belirleyeceğiniz çelik kasa ölçüleri, muhafaza edeceğiniz eşyalarınızın kasaya sığmasını engelleyebilir. Çelik Kasanın yerleştirileceği yer ile ihtiyaç duyduğunuz minimum iç ölçüler birlikte değerlendirilmelidir.

d. Çelik kasa uzun ömürlü bir eşyadır. Bu nedenle yeni bir çelik kasa alırken, yer problemi yoksa, ileriki zamanlarda ortaya çıkabilecek ihtiyaçları da göz önünde bulundurmak ve yeterince büyük bir çelik kasa almak gerekir. Kasanın büyük olması güvenlik ihtiyacının karşılanmasında da avantaj sağlayacaktır.

II. Güvenlik ihtiyacının seviyesi ve tipini belirleyin.

a. Dışarıdan gelebilecek tehditlere karşı güvenlik,

b. Ev veya işyerinizde, çocuklara veya diğer çalışanlara karşı güvenlik,

c. Yangına karşı güvenlik

III. Kasanın bulunacağı ortamın mevcut güvenlik koşulları kötü niyetli kimselerin çelik kasa üzerinde hangi süreyle rahat çalışmasına izin verebilmektedir. Bu çelik kasanın güvenlik seviyesini ve mümkün ise yere sabitlenip sabitlenmemesini belirlememize olanak verecektir.

a. 5 dk. Sürebilecek saldırıya karşı güvenlik

b. 15 dk sürebilecek saldıra karşı güvenlik

c. 30 dk sürebilecek saldırıya karşı güvenlik

d. 30 dk üzerinde sürebilecek karşı güvenlik

IV. Kilit sistemini belirleyin

a. Çelik kasalarda kilit sistemi en önemli güvenlik parametrelerinden birisidir. Çelik Kasa üzerinde anahtarlı kilit, elektronik şifreli kilit ve çevirmeli kilit sistemleri tek başına veya kombine şekilde bulunabilir. Tecrübelerimiz kasa üzerinde bir adet elektronik şifre ve bir adet çevirmeli (mekanik) bulunmasının güvenlik avantajı sağladığını göstermektedir. Kaliteli bir elektronik şifreli kilit en iyi korumayı sağlayacaktır.

b. Önerdiğimiz şifre ve kilit markaları; Kasataş, M-lock, Stuv, Mauer, La Gard veya Sargent & Greenleaf

c. Kilit sistemlerinde en üst düzey güvenlik için satış danışmanınızdan “Cam Kilit” hakkında bilgi alın.

V. Çelik kasanın sac kalınlıklarına ve dolgu malzemesine dikkat edin.

a. Sac kalınlıkları, kullanılan dolgu malzemesi ve kapılarda kullanılan fitiller çelik kasanın güvenlik düzeyini, ısı geçirmezliğini doğrudan etkilemektedir. Güvenlik ihtiyacınızın seviyesine bağlı olarak tercih edebilceğiniz farklı özellikler sunulmaktadır.

VI. Çelik kasanın TS EN 1143-1 güvenlik sertifikası var mı?

a. TSE, ECBS, SP ya da UL gibi Uluslararası sertifikasyon kuruluşları, çelik para kasalarını testlerden geçirerek, standartlara uygunluğu kontrol eder ve dünya çapında bir güvenlik standardizasyonu oluştururlar. ISO 9001:2008, Satiş sonrasi Hizmet Yeri Yeterlilik Belgesi ( SSHYB ) ve TS EN 1143-1 sertifikası, alacağınız çelik kasanın güvenlik seviyesinden emin olmanıza olanak vermektedir.

VII. En Önemlisi İse Çelik Kasa nereden Alınır.?

Çelik kasa alırken ucuz olsun diyerek insanlar genelde araç üzerinde kasa satan kişilerden kasa almaktadır. Bu çok yanlış bir uygulamadır. Çünkü bu tür firmalar bir daha telefonla ulaşmanız mümkün olmayabilir. Çelik Kasanızın herhangi bir sorunu olduğunda servis veremeyebilir. Ve bu tür kasa satan firmalar ucuza satabilmek için kasanın kalitesini de düşürmektedirler. En önemlisi ise bu firmalardan bazıları önceden yedek anahtar yaptırıp kasayı satarken satın alan kişinin adını adresini ve kasayı nereye koyduğunu bildiklerinden dolayı daha sonraki zamanlarda ellerindeki yedek anahtarlarla hırsızlık yapmışlardır. Bunların bir çok örneği mevcuttur.

Çelik Kasa Alırken fiyatından daha çok firmanın uluslararası geçerliligi olan sertifikalarının olup olmadiğina muhakkak sorunuz mesela ( ISO 9001:2008 ,TS EN 1143-1 ve SSHYB vb. ) güvenirliliğine, üretici olup olmadığına, kaç yıldır bu işi yaptığına, referanslarına , gelecekte size servis verip veremeyeceğine bakılması gerekir. Ucuz olan kasa iyi kasa demek değildir. Çünkü kasanın içinde belki de yıllardan beri birikimlerinizi, paranızı mücevherlerinizi ve sizin için önemli olan manevi değerlerinizi saklayacaksınız. Bu nedenle ucuz kasa değilde güvenilir firmadan kaliteli kasa almanızı öneririz.( Unutmayınız ingilizlerin bir sözü var ucuz mal alacak kadar zengin degilim derler. )

Akdeniz İhracatcilar Birlikleri

AKİB DEMİR BİRLİĞİ

No:15782

Tarih: 22.02.2003

|

|

|

|

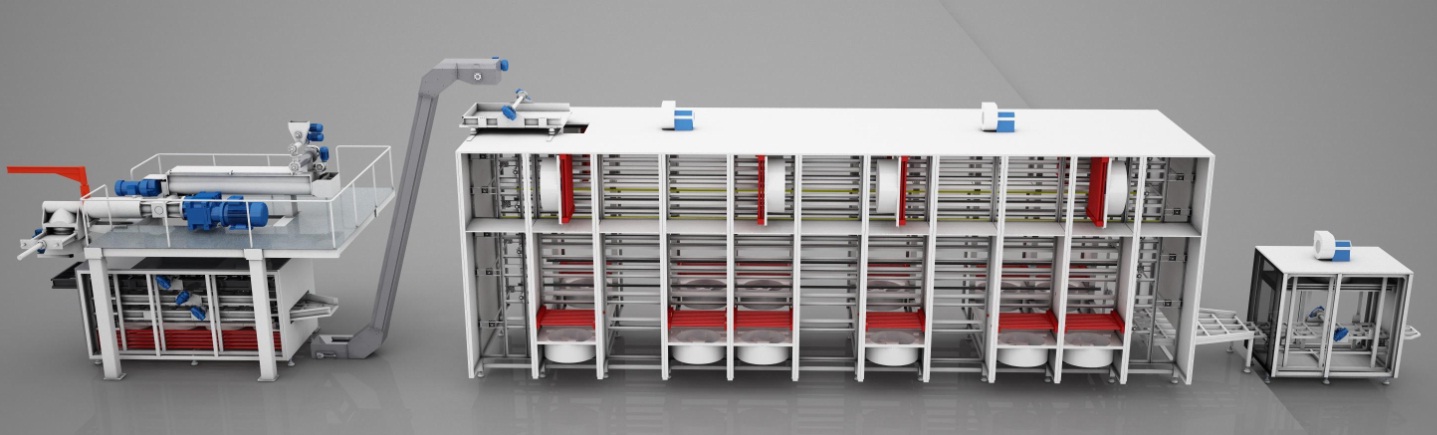

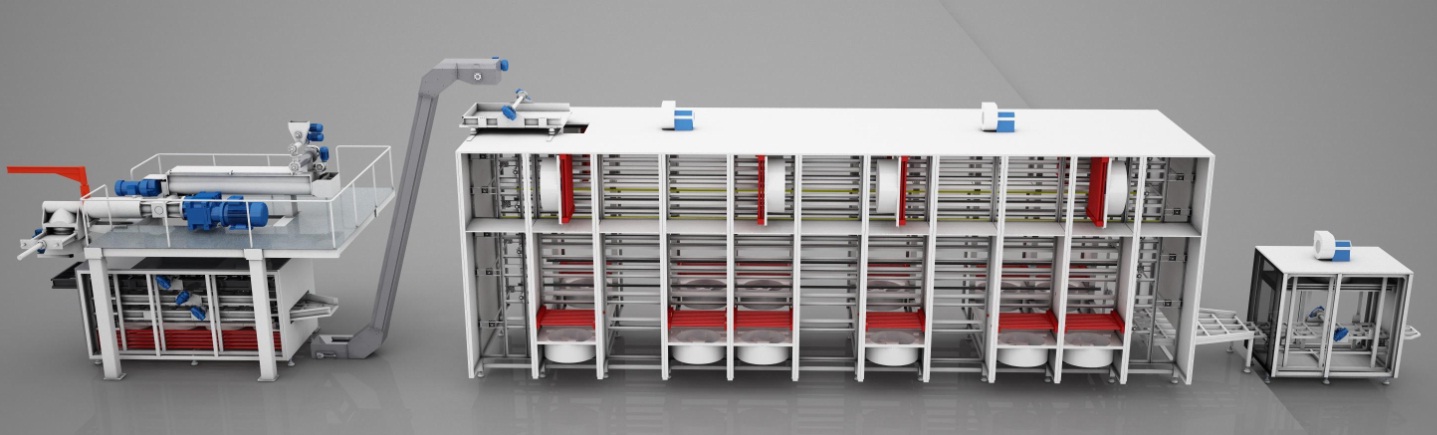

SAATTE 500KĞ KESME MAKARNA MAKİNASI ( 699.000€ )+KDV FİYAT TEKLİFİ EKTEDİR SPAGETTİ HARİÇ 15 ÇEŞİT MAKARNA ÜRETEBİLİR

|

SAATTE 500KĞ KESME MAKARNA MAKİNASI ( 699.000€ )+KDV FİYAT TEKLİFİ EKTEDİR SPAGETTİ HARİÇ 15 ÇEŞİT MAKARNA ÜRETEBİLİR

|

| Açıklama: |

Subject: 500 Kg/h

Shrot Cut Macaroni Line

PROFORMA INVOICE

Packing

Excluded

Material delivered

The delivery is based on EXWORKS GAZIANTEP, TURKEY.

Payment terms

Payment, cash or 100% confirmed irrevocable L/C, to be opened with order with a first class bank and to be confirmed by the latter, covering the whole period of manufacture and allowing partial shipments, available as follows:

50 % by order confirmation

50 % against presentation of shipping documents.

Object:

Automatic continually working short goods production line with drying process utilizing high temperature ( hot water at 95- 100 � degrees to the coils ) able to produce 500 kgs/hour ( 0,5Tons /hour ) of short-cut product

SHORT CUTTING LINE

With a capacity of 500 kg/hour

The System consists of following main units:

1. Pressing Unit.

2. Vacuum pomp

3. Shaker

4. Pre-drying

5. Shaker and coller

6. Resting Silos

7. Aır Conditioning - Main Control Panel

8. Thermal Control Center.

9. Buckets �Z� Elevator

PRODUCTION WARRANTEE

All Pasta Lines can use both semola from durum wheat or flours from soft wheat.

Automatic continually working short goods production line with drying process utilizing high temperature ( hot water at 95 - 100� degrees to the coils ) able to produce 500 kgs/hour (0,5 Tons hour )

Production Capacity: up to 500 Kg/h.

Dry pasta seeming specific weight: up to 400 Kg cubic meter.

Dry pasta thickness: 1,1 mm max.

Format max length: 5 cm.

Warrantee format: on five different formats of common choose, provided that seeming specific weight and length are adequate.

Output 500 Kp/hour. Hourly capacity can vary +/- 10% depending on type of pasta (raw material, shape, die, etc.)

The production capacity of the line is to be conventionally referred to:

Dry product, with legal and not superior to 12,5% humidity.

Continuous and uninterrupted production of the guaranteed shape for 24 hours cycle.

Aluminium belts manufactured with slotted slats carried by chains.Self-adjustable feet allowing to level machines to any

Type of floors.

Steel supporting frames which grant stability and a longer lifetime of the whole installation.

Hydraulic plant complete with 3-ways pneumatic valve, pump, by-pass, control valve, gauges and thermometers.

Air exchange systems realized with steel channels and butterflies equipped with air suction and air input electrofans with pre-heating batteries.

High performance axial fans with electric motors suitable for high temperature Electrical axial fans provided with high temperature �h� class special electrical motors and aluminium cast fans with adjustable blades.

Shaker and cooler equipped with a new conveying system with independent vibrating motors for each floor, controlled by to optimize the dwelling time for each pasta shape

1 Continually worked hour

Dries short-cutting product having 400 mm, special weight types 300 - 400 kg/mc, 500 kg/h, and mm. 1 dimensional thickness .

12,5% to +/- 0,5% final humidity.

The line productive capacity will depend on soft wheat flours ability to make pasta, in case of flours or blends use.

The line can produce every pasta format above-named, even with the use of semolina and soft wheat flour blends.

The line nominal productive capacity could undergo some changes in operation of additive type and quantity.

The Production Capacity Refers To The Following Technological

500 kgs/h of dried short-cut product , 300 - 400 kg/mc specific weight shape and with mm. 1 sizes thickness.

Final humidity 12,5 % with a tolerance of +/-0.5 % on the base of the whole quantity of lasagne laid on trays.

Whenever 100% of durum wheat semolina is used, 70% raw materials gradation must be comprehended between 300 and 180 micron and at any case 30% left must never be higher than 400 micron of gradation.

In order to obtain the dough, it�s at your charge the water supplying according to the International Health Organisation, cleaned, colourless, odourless, tasteless, with no chlorine and/or ammonia residues, with no suspended particles greater than 5 micron.

Inlet overheated water supply to machine batteries at least 95- 100� C must be provided by the clientect.

Water supply to the dough with a flow of 150 lt/h at least,pressure 1.5 bars at least must be granted by the client; you will also take care of water supply to the dough at the temperature you require to obtain the technological process.

Continuous and uninterrupted production of the guaranteed shape for 24 hours cycle.

Hot Water at a temperature no lower than 95- 100 �C, for feeding of all technologic heating control systems present in the line.

1-PRESS MODEL HMP 1-140 K 400 :

The dough touching surfaces of the pressing unit are stainless steel.Semolina and water that will be mixed shall automatically be poured to the vessel. There are 1 pieces of macaroni mould with CIRCULAR DIES having Diameter of 400 mm Chromed cutting surface, complete with special interchangeable Teflon insertsand 5% of spare inserts Shape to be defined with thickness 0.9-1,1 mm. Macaroni moulds have the technology that can be disassembled and assembled by hydraulic system.Pressing Unit system operates full automatically.

Technical features:

N.1 Stainless steel Compression Screws � High resistant carbon steel (Fe 400) compression cylinders with stainless steel jacket for cooling by means ofthermal adjusted water;high efficiency-type compression screws (� 140 mm); constant pitch; variableprofile on the whole length; triple start; made in stainless steel (304);main independent reduction gear with ground teeth gears, slow shaft drilled andfitted out with chromium-coated ring, replaceable in case of wear out, withholding gaskets application; compression screws drive motor;

N.1 Short Cut Pasta Die-Head (� 400 mm)

It consists of a high resistance steel casting suitable to house circular dies,equipped with a pushing unit to allow a quick change of dies and also with stainless steel outer jacket for thermostatic water circulation during operation.

Pressure gauge with concerning electrical safety contactsare of course included.

İndependently working button panels installed at press foot in mixing tanks zone. repeated orders to electrical general panel.

Pressure gauge with concerning electrical safety contacts are of course included.

The device is provided with knives with one, two or three blades and naturall some spare blades.

N.1 CIRCULAR DIES with Diameter = 400 mm

Chromed cutting surface, complete with special interchangeable Teflon inserts and 5% of spare inserts Shape to be defined with thickness 0.9-1,1mm

Electric Hoist

Swiveling hoist for die lifting, 200 kg maximum hanging load each.

Semola Dosing

Feeding from the barrel with presettingof the semola weight electronically controlled from inverter to independent geared motor.

Water Dosing

Composed by circuit with stainless steel piping. 2-way pneumatic valve .Thermometer and manometer.Inter ception solenoid valve.Sundry stainless steel connections.The above components are supplied in �pre-assembled� version.Minimum required pressure is 1,5 bar, � STABILIZED�

Centrifugal Pre-mixer stainless steel, consisting of :

Horizontal tank made to be easily opened.Shaft with extractible paddles.

Cover opening on the side opposite to motor, provided with mechanic security system.

Direct Motor with 900 Revs. 2,2kW

Entering of the liquid product on both sides.

Entering of semola in the acceleration pre-chamber.

Hydraulic or mechanical-type die-change tool with side extraction-insertion system, equipped with hoist for lifting of die.

The unit consists of ;

Cyclone

Dosage Unit

Vessel (Mixer)

Small Helical screw (Cross Helix)

Big Helical screw

Head Part (Moulding Unit)

Knife Cutting System

Knife Aeration Fan

Press Platform

Hydraulic System (For assembling and disassembling of mould)

Vacuum System and Pump.

Short cutted pasta die in Bral 400 mm, inserts in Teflon.Test format 210

2.VACUUM PUMP WITH OIL SYSTEM

For centralized system complete with storage tank with automactic function,radiator cooling and control panel.

Vacuum system:

Ring type with pump connection collector and distirbution to the production area with on-off valve insertion for 1 production lines, in SS 2� dia,black piping

3. SHAKER

Shaker unit is the section where the initial moisture of the material is removed which is coming from the press unit cut and humid .The product retains in this unit about 1 or 2 minutes. The material's initial moisture is reduced by ventilators and suction fans operating inside. The stock, then, is transferred to the 1st Drier by and elevator.

The unit consists of ;

Sieve Eccentric Motion System

40 mms thickness metal polyestr panels internally lined with steel which opens fully bymeans of special butt strap rods to make maintenance and clean-up operations easier.

Electrical axial fans provided with high temperature �h� class special electrical motors and aluminium cast fans with adjustable blades.

Sieve Suction Fan

shaker on support legs off the ground provided with bottom nsulation board.

Sieve Heating System (Serpentine and heating pipes)

4.DRYER - MODEL HM-D 11/ 9P

Pre-drying section,drying section an stailization section.

Belt Width :1,70 mm

Overall net area: 119,6 sq. mt.

Process Time: approx. 5 hours at high temperature.

First drier is composed of 11 m long tunnel with 4 stages. The touching surfaces where macaroni is dried are made of anodic oxidized aluminum and outer covers was produced from a material providing heat insulation with interior part made up of polyurethane material and outer part is made of white dyed iron sheet which meets international food processing regulations. In the first drier, high portion of

the moisture is removed. The moisture content is decreased from 30 -29 % to 19 -18 % within 45 minutes retention time. Heat and moisture control are controlled by automatic conditioning system.

The second drier is also composed 11 m long tunnel but 5 stages and the materials used are identical with the 1st drier. This is the main section that the product takes its color and shape. So, the real drying section is second drier which directly effects the final product quality. The moisture content of the material is decreased gradually from 19 - 18% to 12 - 12.5 %. Again, heat and moisture control are controlled by automatic conditioning system. Drying period of the product is approximately 5-5.5 hours.

The units consist of ;

Vibrant Product Distributing System

Product Drying Bands ( 11 M long, 9 decks) Anodic oxidized Aluminum

Drier Operating Drive Group (4 pieces)

Ventilators inside Driers ( 20 pieces)

Outer Air Suction Fan ( 2 pieces)

Product Output Unit ( Vibratory)

Air conditioner Checking System ( For product control ) H. Heating System for 1 & 2 driers

(3 ways valve, serpentine, heating pipes, circulation pumps, etc)

5. COOLER UNIT 1H 2 M

The main components of the unit are the following:

One passage boards coller.

Pasta cooling, at deperession drop, with air.

External insulating panels made of flame retardant polyurethane and extruded aluminium frame sections; panels are easy to open for inspection and maintenance operations.

Frame structure in enamel-treated carbon steel sheets.Stainless steel support structure for insulating panels and drive unit.

Vibrating level, made of stainless steel tubular frame with stainless steel wire mesh,the drive shaft is connected with the vibratory motors

No. 3 Axial-type Motor Units for ventilation, air intake and recycling, complete with servo-driven dampers.

Set of electrical materials for connection to outside power supply, complete with teflon-coated conductors, aluminium raceways, terminal boxes and accessories.

6.RESTING SILOS:

Number of silos: 4 x 8 m3 /each.

Approx. overall capacity: 9,6 tons (referred to product with specific weight 400 kg/mc)

Consisting of the following:

Number of silos: 4 x 8m3/ each.

Approx. overall capacity: 9,6 tons.

Consisting of the following:

No. 1 bucket elevator model HMS-350

No. 1 fixed concave belt conveyor model H 400

No. 1 fixed bidirectional belt conveyors model H 400

No. 1 movable bidirectional belt conveyors model H 400

Equipment for 4 cell of storage silos :

4 Downloading Spirals

No. 1 fixed belt conveyors model H 400

No. 1 vibrating sifters model HMV-1000/1.2

Lateral Panels, Top Panels, Global Metal Frame, Bottom Cone, Ladders and gangway for the storage group of 4 silos are excluded.

6.AIR CONDITIONING - MAIN CONTROL PANEL:

This panel is designed with touch panel PID automation system fully controlling of succesful drying process. PID control system allows precise and full control of moisture parameters in every stage of drying process. And this directly effects the success ofn the final moisture content of the macaroni to be produced.

Following applications are managed by Air Conditioning Control Panel

The filing and archive for various types of macaroni receipts

The alarm for troubleshooting

Code protection for access for modification on the data

The calculation of average production

The electronic and electrical materials are chosen rom the worldwide branded high quality suppliers having CE certificates.

The units consist of ;

Motorized rolling shutter for pre-drying air intakes.

Pneumatic modulating servo-motor (Siemens Control brand) for the rolling shutters and/ or air scoop butterfly contro

Feeler Elimko for reading, control and temperature/ humidity adjustment, in each control clime area

Electric motor internal line, degraded,protection level IP 55, isolation class H .

Control and security devices.

Internal heating system, flanged and welded drying, pre-set up to drying roof. Pipes and steel joint, to low carbon contents.

With a adjusting temperature valve each, circulation electro pump, interception valves, no return valves, filter, thermometer and monometer. Flanged construction and welded PN 16.

Steel to low carbon contents pipes and connection.

8 .THERMAL CONTROL CENTER:

Boiler tank having 200000 Kcal / h to meet the requirement of the line

insulation and necessary accessories

Hot water pipes.

Expansion tank

Hot water pumps

The necessary technical information for the type of the fuel to be combusted has to be given us by the customer.

9.BUCKETS �Z� ELEVATOR

Buckets with polyemit structures and net.

Buckets length : 350 mm

�Z� conformation.

Modular carrying structure.

Structure modules made of strong iron plate pressedfolded and carbon steel

section-piece.

Structure base fixed on adjustable supports, lifted from floor of 100 mm about.

Base with drawer to raise possible pasta rejects.

Command by motor-reducer.

Mechanical security by torque limiter.

Buckets movement by carbon steel chains pitch:

SHORT CUTTING LONE PRESENT MOTOR NAMES AND POWERS

PRESSING UNIT

QTY

POWER kW

TOTAL kW

Dosage Motors

2

0,37

0,74

Dosage Speed Mixser

1

2,2

2,2

Vessel Motor

1

7,5

7,5

Small Helix Motor

1

7,5

7,5

Big Helix Motor

1

22

22

Mould Aeration Motor

1

0.75

0.75

Knife (Cutting) Motor

1

1,1

1,1

Hydraulic System Motor

1

2,2

2,2

Pressing Unit Total Power 9 43,99 kW

SHAKER

QTY

POWER kW

TOTAL kW

Sieve Motion Motor

6

0,2

1,2

Aeration Motors

3

1,1

3,3

Sieve Suction Fan Motor

1

0,55

0,55

Shaker Unit Total Power 10 5,05kW

FIRST DRIER

QTY

POWER kW

TOTAL kW

Vibro Motor Distributor

2

0,2

0,4

Drier Propulsion Motor

4

0,75

3

Aeration Ventilator Motor

12

1,1

13,2

Aeration Ventilator Motor

8

1,1

8,8

Suction Fan Motor

2

1,1

2,2

Output Vibro Motor

2

0,2

0,4

Elevator Motor

2

0,75

1,5

First Drier Total Power 32 29,50 kW

SHAKER AND COLLER

QTY

POWER kW

TOTAL kW

Sieve Motion Motor

1

0,75

0,75

Aeration Motors

1

1,1

1,1

Sieve Suction Fan Motor

1

0,37

0,37

Shaker Unit Total Power 3 2,22 kW

OTHER EQUIPMENTS

QTY

POWER kW

TOTAL

Circulator Pump

4

0,2

0,8

Over Silo Bands

2

0,50

1

Under Silo Bands

1

0,50

0,50

Output Vibro Motor

2

0,2

0,4

Vacuum Pump Motor

1

5,5

5,5

Other Equipment Total Power 10 8,20 kW

OVERALL DIMENSIONS OF SHORT GOODS PASTA LINE

Approximate space occupied by a short goods pasta line � capacity 500 kg/h

Capacity

H

A

B

C

D

E

J

G

F

W1

W2

500 Kg/h

21500

3500

2500

11000

1500

3000

5000

5050

4200

3700

3400

Note: All dimensions are expressed in mm

INSTALLED POWER FOR SHORT CUT PASTA LINE RATED 500 Kgs/hs

1 INSTALLED THERMAL POWER

200000

Kcal/h

2 ABSORBED THERMAL POWER

145000

Kcal/h

3 TEMPERATURE OF OVERHEATED WATER

>= 100

�C

4 INSTALLED ELECTRIC POWER

150

kW

5 ABSORBED ELECTRIC POWER

88,96

kW

6 PRESSURE OF COMPRESSED AIR

7

Bar

7 VACUUM

100

m3/h

8 WATER FOR DOUGH

150

l/h

9 STABILIZED PRESSURE OF DOUGH WATER

> 1,5

Bar

Without explicit applications, how much described in offer will be built according to the Normative of European Union

EXCEPTIONS (ON CUTOMER'S ACCOUNT):

The flight tickets and in-country transfers from/to airport, hotel, site of the technicians.

Accomodation (hotel and food) and telephone calls.

$ 200 pocket money per week per person.

PAYMENT CONDITIONS;

Payment, cash or 100% confirmed irrevocable L/C, to be opened with order with a first class bank and to be confirmed by the latter, covering the whole period of manufacture and allowing partial shipments, available as follows:

50 % by order confirmation.

50 % against presentation of shipping documents.

The delivery is based on EXWORKS GAZIANTEP, TURKEY.

SECTIONAL PRICES OF THE SHORT CUTTING LINE 500 Kg/h

Pos.

Description

EXW Price / USD

1

SHORT CUT DRY PASTA LINE WITH CAPACITY OF500 KG /H

1

VACUUM PUMP 100 m3/h

1

Thermal Control Center 200.000 Kcal/h

1

Pressing Unit

1

Shaker

1

Pre-drying

1

Aır Conditioning - Main Control Panel

2

Buckets �Z� Elevator

1

9,6 TONS DRY PASTA SILOS INCLUDED IN PRICE

1

Shaker and coller

1

500 GR Packaging Machine

TOTAL

525.000€

MANUFACTURING AND INSTALLATION PERIOD :

The manufactruing period is after 120 ''One hundred and twenty' days after receiving the advance payment.

Installation and start up period is 60 days .

The electrical connections of the abovmentioned system's equipments cover the inside of the building only

Besides the outer ligthnig of the equipments, all converters, low tension transformer, havaii line, underground cables to the inside of the building, and plant inner and outer lightning are excluded.

The potable water installations which is required for the plant and its infrastructure is excluded and on customer's account.

Due to the delay which negatively effects the installation period adversly, because of the delay of supply of the necessities and equipments by the Customer, KASATAS A.S. dully will not have responsibility for this installation period delay.

Lifts and forklifts etc and necessary equipments for the unloading off the trucks and transfer to the site will be done by the Customer.

The necessary workmanship support to the KASATAS A.S. technicains will be held by the customer.

Main Control Panel is controlled by touch screen automation system.

Air Conditioning Control Panel is controlled by touch screen PID automation system.

GUARANTEE PERIOD AND TERMS

The machine and equipments guarantee is 14 months beginning with start up of the system.

To operate the plant within guarantee period, Customer shall conform Seller�s instructions and obligations. Seller shall not be responsible for any material wear that cause defects, negligence and professional faults within maintenance and operation.

The necessary maintenance and lubrication instructions during the guarantee period will be given by a chart and strictly Customer has to comply this instructions.

Any modifications made without confirmation of KASATAS A.S., The guarantee is invalid.

The short macaroni line works as continuous system.

The control panel and electrical motors will be chosen from CE certificated brands and suppliers.

ACCESSORIES SUPPLIERS AND BRAND NAMES THAT WE USE IN OUR LINES

PRESS 1.

BRANDNAME

MAIN SCREW CONVEYOR MOTOR

GAMAK

MAIN SCREW CONVEYOR GEAR BOX

YILMAZ

CROSSWISE SCREW MOTOR

GAMAK

CROSSWISE SCREW REDUCER

YILMAZ

TROUGH MOTOR

GAMAK

TROUGH REDUCER

YILMAZ

DOSER MOTOR

GAMAK

DOSER REDUCER

YILMAZ

FLOUR VIBRO CYCLONE

OMB

FLOUR SCREW MOTOR

GAMAK

FLOUR SCREW REDUCER

YILMAZ

HYDRAULIC UNIT HEMES

(300 / H 2,2)

KNIFE FAN HEMES

( 300 / F3)

KNIFE FAN MOTOR

GAMAK

KNIFE MOTOR

GAMAK

KNIFE REDUCER

YILMAZ

VACUUM PUMP

GÜCÜM

MOULD CRANE

KL

SHAKER

BRANDNAME

VIBRO MOTOR

OMB

FAN MOTOR

GAMAK ( H CLASS )

FAN FLAP

HES ( 1 / 60 )

ASPIRATÖR

HES ( 1 / A3)

DRIER

BRANDNAME

VIBRO SPREADER MOTOR

OMB

MOTION MOTOR

GAMAK

MOTION REDUCER

YILMAZ

FAN MOTOR

GAMAK ( H SINIF )

FAN FLAP

HES ( 1 / 60 )

ASPIRATOR

HES ( 300 / AA3)

ELEVATOR MOTOR

GAMAK

ELEVATOR REDUCER

YILMAZ

HOT WATER VALVE

DUYAR

3 WAY HOT WATER VALVEI

SIEMENS

HOT WATER PUMP

GURNFOS

OUTLET SHAKER MOTOR

OMB

COOLER

BRANDNAME

VIBRO MOTOR

OMB

FAN MOTOR

GAMAK ( H CLASS )

FAN FLAP

HES ( 1 / 60 )

ASPIRATÖR

HES ( 1 / A3)

SILO

BRANDNAME

TOP BAND MOTOR

GAMAK

TOP BAND REDUCER

YILMAZ

MOBILE BAND MOTOR

GAMAK

MOBILE BAND REDUCER

YILMAZ

BOTTOM BAND MOTOR

GAMAK

BOTTOM BAND REDUCER

YILMAZ

ELECTRICAL COMPONENTS ACCESSORIES SUPPLIERS AND BRAND NAMES

THAT WE USE IN OUR LINES

CONTROL PANEL

1. BRANDNAME

2. BRANDNAME

MAIN SCREW IINVERTER

SCHNEIDER

SIEMENS /ABB

CROSSWISE SCREW INVERTER

SCHNEIDER

SIEMENS /ABB

DOSER UNIT INVERTER S

SCHNEIDER

SIEMENS /ABB

KNIFE SYSTEM INVERTER

SCHNEIDER

SIEMENS /ABB

DRIER INVERTER

SCHNEIDER

SIEMENS /ABB

CONTACTORS

SCHNEIDER

SIEMENS /ABB

GROUP AUTOMATS

SCHNEIDER

SIEMENS /ABB

MASTER SWITCH

SCHNEIDER

SIEMENS /ABB

PLC CONTROL

FACON |

| Anahtar Kelimeler: |

|

| Tarih: |

20.11.2012 14:40 |

| Beğenilme: |

43802 |

| İndirilme: |

0 |

| İzlenme: |

0.00 (0 Oylama) |

| Dosya Boyutu: |

142.9 KB |

| Ekleyen: |

Administrator |

|

|

| Fiyat: |

699000 €+KDV €

999999 €+KDV

KDV Dahil: 838.800,00 €

|

|

|

|

Malın Satış Fiyatı ve Birim Fiyatının Uygulanmaya Başladıgı Tarih: 01.01.2026

Üretim Yeri: GAZİANTEP

|

|